Unleash Your Creativity with Woodworking for Furniture Projects

|

| Woodworking for furniture making and repair |

Woodworking for furniture making and repair

A. Brief overview of furniture making and repair

Woodworking for furniture making and repair: Furniture crafting and restoration form a dynamic duo in the realm of woodworking. It encompasses the art of envisioning, constructing, and upkeeping various pieces of furniture. When it comes to furniture making, the process revolves around the transformation of raw materials such as wood, metal, or plastic into functional and aesthetically pleasing creations.

On the other hand, furniture repair revolves around reviving damaged furniture and restoring it to its former glory. Let's delve into the fascinating world of furniture making and repair, considering some key aspects:

1. Furniture Making:

- Design: A crucial initial phase involves envisioning the furniture's form, structure, and overall aesthetic appeal.

- Material Selection: Deliberating upon the choice of materials that best suit the intended design and purpose of the furniture.

- Cutting and Shaping: Employing traditional woodworking tools or modern technologies like computer-aided design (CAD) software and CNC machines to cut and shape the materials into desired components.

- Assembly: Skillfully joining the components together to create a sturdy and visually captivating piece of furniture.

2. Furniture Repair:

- Fixing Broken Parts: Identifying and mending any damaged or fractured sections of the furniture.

- Replacing Missing Pieces: Procuring or recreating any components that are absent or beyond repair, ensuring the structural integrity of the furniture.

- Restoring Finish and Color: Applying techniques such as carving, sanding, staining, and polishing to bring back the furniture's original luster and hue.

Furniture making and repair demand a blend of technical prowess, artistic acumen, and meticulous attention to detail. In these domains, you have the opportunity to unleash your creativity and explore innovative ideas. Moreover, you can delve into the realm of various wood types, joinery techniques, and design styles.

Whether your interest lies in crafting bespoke furniture or breathing new life into cherished antique pieces, both furniture making and repair hold immense potential for a gratifying and enriching career or hobby. So, get ready to embark on an exciting journey of DIY projects, where the magic of woodworking and furniture craftsmanship awaits!

|

| Importance of techniques in furniture making and repair |

B. Importance of techniques in furniture making and repair

The Significance of Techniques in Woodworking and Furniture Projects

Woodworking and furniture projects have been honed and celebrated for countless ages. The techniques employed in woodworking and furniture making are of paramount importance as they contribute to the endurance, robustness, and alluring charm of the furniture. Here are some pivotal points to ponder when delving into the significance of techniques in woodworking and furniture projects:

1. Preservation of furniture:

- Joinery, a cornerstone technique, ensures the structural integrity of furniture by securely fastening pieces of wood together. This steadfast union withstands the test of time, warding off any future disassembly.

- Employing appropriate finishing techniques is crucial for safeguarding furniture from unsightly scratches, dents, and other forms of damage. By doing so, the lifespan of the furniture is significantly prolonged.

2. Aesthetic allure:

- Embracing furniture techniques plays a pivotal role in elevating the visual appeal of the final product. Through meticulous sanding and finishing techniques, even the most ordinary pieces of furniture can be elevated to the realm of exquisite artistry.

- The art of upholstery further enhances the allure of furniture. By introducing vibrant colors, inviting textures, and added comfort, upholstery transforms furniture into captivating pieces that beckon.

3. Repair and restoration:

- Furniture repair techniques are indispensable when it comes to breathing new life into damaged or antique pieces. With the aid of proper techniques and tools, cracks, splits, or chips in furniture can be skillfully mended, restoring their former glory.

- Restoration techniques are a gateway to reviving the original splendor of antique furniture. By employing these techniques, furniture is returned to its former grandeur, allowing its timeless beauty to shine once again.

In the realm of woodworking and furniture projects, techniques serve as the cornerstone for preserving, fortifying, and enhancing the aesthetic appeal of furniture. Whether you find yourself as a seasoned furniture maker or an enthusiastic DIY projects devotee, grasping and implementing these techniques is key to attaining the desired results.

|

| Furniture Making Techniques |

Furniture Making Techniques

A. Joinery Techniques

Joinery techniques are the backbone of woodworking, offering ingenious ways to connect wood pieces sans the need for nails or screws. These techniques, requiring precision and skill, guarantee robust and enduring joints. Let's dive into three commonly employed joinery techniques that will take your DIY projects and furniture craftsmanship to the next level:

- Mortise and Tenon Joint: A stalwart among joints, this technique involves crafting a rectangular hole, known as a mortise, in one piece of wood, complemented by a matching projection called a tenon on the other piece. The tenon snugly fits into the mortise and is further secured with the adhesive properties of glue. The popularity of this joint stems from its exceptional strength and remarkable resistance against racking.

- Dovetail Joint: Recognizable by its enchanting interlocking shape, reminiscent of a dove's tail, the dovetail joint is a true work of art. It is formed by skillfully cutting a series of angled pins on one piece of wood that seamlessly interlock with corresponding tails on the other piece. Renowned for its unwavering strength, the dovetail joint is a common fixture in furniture construction, ensuring longevity and structural integrity.

- Dowel Joint: Simplicity and affordability are the hallmarks of the dowel joint. This technique entails drilling holes into each piece of wood and subsequently inserting wooden dowels, which are securely glued in place. The dowel joint provides a robust connection, reinforcing the bond between the two pieces of wood. Its popularity lies in its straightforward execution and cost-effectiveness.

Joinery techniques play an instrumental role in woodworking endeavors, wielding the power to elevate the strength and durability of your final products. Mortise and tenon, dovetail, and dowel joints are merely a glimpse into the vast array of techniques available to passionate woodworkers, each with its own distinctive advantages and disadvantages. By embracing and mastering these techniques, craftsmen can bring forth magnificent, enduring pieces that will stand the test of time.

|

| Shaping Techniques |

B. Shaping Techniques

Shaping techniques play a vital role in the realm of manufacturing and production. These techniques serve to metamorphose raw materials into desired forms and sizes, and two widely embraced methods are hand shaping and power shaping.

Hand Shaping:

Hand shaping, an artisanal technique, hinges upon the adept use of manual tools to mold materials. With its versatility, this method finds applications in woodworking, metalworking, and various crafts. The beauty of hand shaping lies in its ability to bestow unparalleled control over the shaping process, enabling the creation of intricate and meticulous designs. Chisels, saws, planes, and files stand as faithful companions in this manual endeavor.

- Hand shaping entails the artistry of manual tools.

- This technique affords meticulous control and precision during the shaping process.

- Key hand shaping tools encompass chisels, saws, planes, and files.

Power Shaping:

Power shaping, on the other hand, takes the reins with the assistance of mechanical tools. Harnessing the power of grinders, sanders, lathes, and routers, this technique surges ahead in large-scale manufacturing and production endeavors. By virtue of its velocity and efficacy, power shaping outpaces hand shaping. Nonetheless, one must exercise caution and implement safety measures due to the high speeds and formidable force exhibited by these tools.

- Power shaping delegates the task to robust power tools.

- This technique boasts swifter execution and heightened efficiency when juxtaposed with hand shaping.

- Prominent power shaping tools encompass grinders, sanders, lathes, and routers.

Both hand shaping and power shaping techniques possess their own set of merits and demerits. Hand shaping grants meticulous control and precision, while power shaping emerges as the faster and more efficient alternative. The choice of shaping technique rests upon the specific requisites and demands of the manufacturing or production process.

C. Finishing Techniques

Sanding

- Gradual Progression: Begin the sanding process with a coarse grit sandpaper and gradually move towards finer grits. This progressive approach ensures that you achieve a smoother and more refined surface.

- Sanding Block for Precision: To maintain even pressure and prevent the creation of uneven surfaces, it's recommended to utilize a sanding block. This tool provides stability and control, allowing you to achieve consistent results.

- Safety First: Prioritize your safety by wearing protective gear such as a dust mask and eye protection. These precautions safeguard against inhaling harmful dust or debris during the sanding process.

Staining

- Test and Evaluate: Before applying the stain to the entire surface, perform a test on a small, inconspicuous area. This step ensures that you're satisfied with the color and compatibility of the stain with the material.

- Even Application: Use a brush or rag to apply the stain evenly, ensuring complete coverage. As you progress, wipe off any excess stain to achieve the desired depth and consistency.

- Patience is Key: Allow the stain to dry completely before moving forward with any sealant or varnish. This ensures that the color is fully set and won't be compromised during subsequent finishing steps.

Varnishing

- Well-Ventilated Workspace: Ensure that you work in a well-ventilated area to maintain a healthy environment. Additionally, wear protective gear such as a dust mask and gloves to safeguard yourself from any potential hazards.

- Smooth and Even Coats: Apply the varnish using a brush or roller, aiming for smooth and even coats. Take care to avoid drips or bubbles, which can mar the final finish.

- Patience for Perfection: Allow each coat of varnish to dry completely before applying subsequent layers. To ensure a flawless surface, lightly sand with a fine-grit sandpaper between coats.

|

| Furniture Repair Techniques |

Furniture Repair Techniques

A. Restoring Structural Integrity

Restoring the structural integrity of various structures, be it buildings or vehicles, is of utmost importance to ensure their safety and functionality. There exist several methods that can be employed to restore structural integrity, encompassing gluing, reinforcing, and replacing.

- Gluing: A widely employed technique, gluing restores structural integrity in materials like wood, plastic, and metal. This method entails utilizing a robust adhesive to bond two material pieces together. The adhesive can be in the form of a liquid or a paste, which is then applied to the surfaces requiring joining. Subsequently, the pieces are held together until the adhesive dries, forming a sturdy bond. Gluing proves to be highly effective in rectifying minor cracks or fractures within a structure.

- Reinforcing: When a structure has gradually weakened, reinforcing comes into play to strengthen it. This method involves introducing additional support to the structure to prevent further damage. Reinforcing can be accomplished through the addition of braces, bolts, or other support structures to the weakened area. It proves particularly beneficial when repairing structures that bear substantial stress, such as bridges or buildings.

- Replacing: There are instances where the damage incurred by a structure is so severe that gluing or reinforcing becomes unfeasible. In such cases, the only viable solution is to completely replace the damaged component. This process necessitates the removal of the compromised element, followed by the installation of a new one. Although replacement often incurs higher costs, it becomes imperative when the overall structural integrity of the entire structure is at stake.

Depending on the type and extent of the damage, gluing, reinforcing, and replacing emerge as effective methods for accomplishing this task. It is crucial to select the appropriate method for each situation to ensure a secure and efficient repair.

|

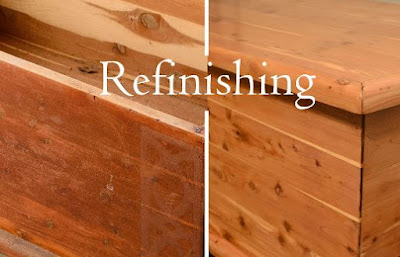

| Refinishing Techniques |

B. Refinishing Techniques